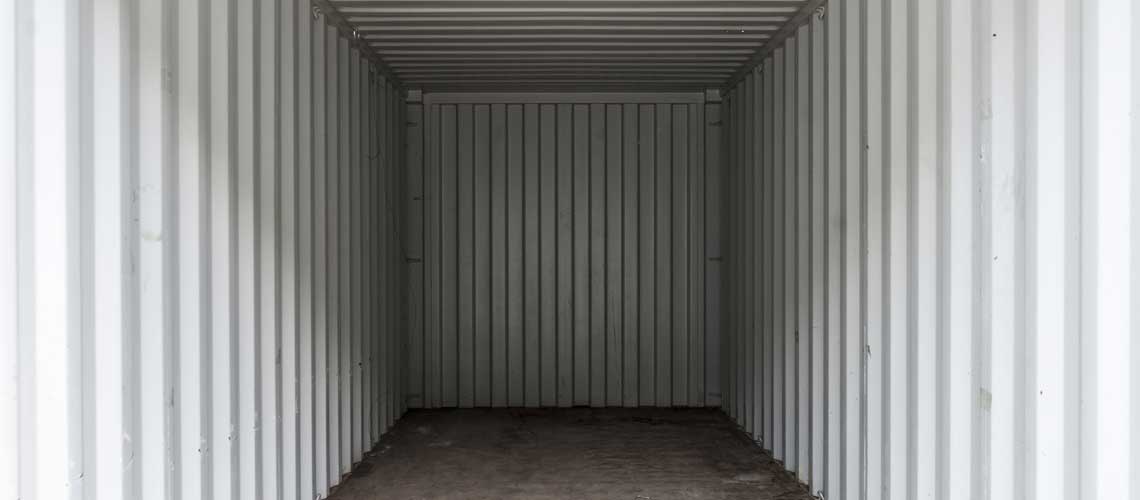

What kind of floors do shipping containers typically come with?

Shipping container floors can vary depending on the type of shipping container you purchase. It is important when getting your shipping container quotes that you inquire about what type of flooring the container is manufactured with. In this blog, we will discuss the different pros and cons.

Ready to purchase a shipping container? Reach out today to get a quote from the best in the industry!

Factors to consider when choosing your floors

PROS & CONS OF MARINE GRADE PLYWOOD

Pro

It can withstand high temperatures, humidity, and the heavy weight placed in the container along with forklift trucks driving in and out.

Con

It attracts pests of all sorts and must be treated with pesticides to protect the goods traveling the world. The odor does dissipate after several years.

PROS AND CONS OF BAMBOO WOOD

Pro

Environmentally friendly

Durable

Easy to maintain

Pest resistant

Con

Easy to Scratch

Requires special Water Sealants

Not always available in shipping containers.

PROS AND CONS OF STEEL

Pro

Protects against moisture, fire, and heavy objects

Pest resistant

Easy to maintain

Recyclable

Con

Not always available in shipping containers

Need help choosing a container? Container Sales Group is here to help. Our team of experts is happy to advise on the best container for your needs and help you through the buying process. Contact us today to get started.

How to replace or install shipping container flooring

Installing or replacing shipping container floors is no easy feat. Unless you work with shipping containers regularly or are a skilled DIYer, you may want to opt for a professional contractor to make these changes… especially if you are installing the flooring as part of a process to convert the shipping container into a living space or business.

However, if you plan to take on this project yourself, the process will look something like this:

- Remove the existing flooring:This will typically involve unscrewingprying up the plywood or bamboo planks from the steel frame. If the flooring is glued down, you may need to use a heat gun or chemical solvents to soften the adhesive.

- Clean the steel frame: Once the old flooring is removed, clean the steel frame thoroughly to remove any dirt, rust, or debris. Use a wire brush or sandpaper to smooth out any rough patches on the steel.

- Measure and cut the new flooring: Measure the length and width of the container and use those measurements to cut the new flooring material to size. If you’re using a material that needs to be glued down, such as vinyl or carpet, apply the adhesive to the back of the material and let it dry according to the manufacturer’s instructions.

- Install the new flooring: Starting at one end of the container, lay down the new flooring material of your choice and secure it to the steel frame using screws, nails, or adhesive. If you’re using plywood or bamboo planks, make sure to stagger the seams to avoid weak spots. If you’re using tiles or other rigid materials, use a notched trowel to spread the adhesive evenly.

- Finishing touches: Once the new flooring is installed, you may want to add trim around the edges of the container to cover any gaps or uneven edges. You can also add a sealant or coating to the flooring material to protect it from moisture, dirt, and wear and tear.

Something else to consider about floors on new containers is that all container floors are treated with Chlordane at the factory as part of an international convention. Chlordane is nasty stuff and the reason for the strong smell. It takes years to go away. Learn more »

or questions or information about shipping container flooring call Container Sales Group. As a Women Owned Wholesaler since 1998 we offer competitive price, and quality shipping containers anywhere throughout the United States. We pride ourselves on the best customer service in this industry.

If you want to have a positive experience and feel confident in your shipping container purchase from start to finish, request a quote or call our office at (888) 320-5938.