The professionals at Container Sales Group help break down your most asked questions about shipping containers. Call us at 888-320-5938.

Shipping containers are strong metal boxes made of Cor-Ten Steel, designed to handle the rugged long journey to transport cargo from place to place and store goods safely. Standardized containers have transformed the shipping and transportation industry, allowing the goods to be moved by rail, road, and ship, as the most common sizes fit onto different forms of transport with ease.

Whether you’re new to shipping containers or a seasoned expert, it’s important to understand the basic anatomy of a shipping container so you know what to look for when buying and maintaining these hardy boxes. Read on to learn more.

Standard Shipping Container Anatomy

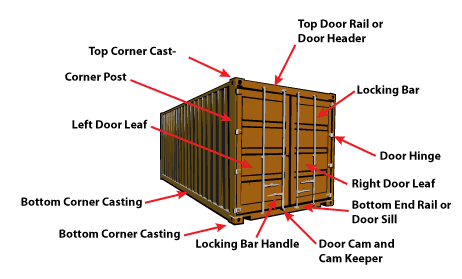

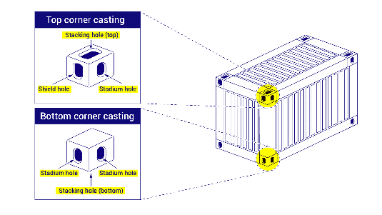

Corner Post / Top Corner Casting

Each corner of a shipping container is fitted with a steel corner post that runs vertically. At each of the corner posts are fittings with an oval opening on the outside. These openings serve to lift the containers or to secure them onboard a vessel, truck, railway wagon, or to connect the container to another container.

Front-End Frame

The structure at the front end of the container (opposite the door end) consists of top and bottom rails attached to the front corner posts and the corner castings.

Top Rail

Longitudinal structural members are located at the top edge on either side of the freight container.

Bottom Rail

Longitudinal structural members located at the bottom edge on either side of the freight container.

Cross-members

Cross members are structural components (visible from underneath the container) that make up the floor. A series of beams spaced every 4” – 6” is attached to the bottom side rail and is the integral part of the floor frame support. The space the cross members create is about 6” between the ground and prevents moisture from seeping into the container from underneath.

One of the reasons that many container structures don’t require a foundation, such as ground-level offices, is the cross members of the floor frame lift the structures away from the ground and mitigate the risk of damage caused by natural elements.

Floor

The floor of a shipping container is typically comprised of 1-1/8” thick marine plywood. In its original condition, the wood floor is suitable for most aftermarket applications.

Roof

Has Corten Steel Sheets with corrugation to give the roof strength and rigidity. The roof of a Shipping Container has corrugations that are heightened portions every 6 inches. The reason for this design is to shed water from the roof to the sides of the container. Avoiding putting too much weight on the roof.

Sides & Front

The side walls are also made of the same corrugated steel as the roof. When it comes to damage on shipping containers, usually the walls take the brunt of impacts and end up with dings & dents & rust as years go by.

Doors

Shipping containers have twin doors on one end, or both ends that open outward to 270 degrees for easy access, loading and unloading. The doors seal shut thanks to the rubber seals and gaskets, keeping them air and watertight, as well as preventing dust and vermin from getting inside.

Now that you know the parts of a shipping container that make up its anatomy, you’ll be better equipped to buy the right container for your needs. Container Sales Group has been selling shipping containers across the United States since 1998. We work hard to deliver consistent, high-level customer service combined with affordable pricing on New & Used Shipping Containers. Call Container Sales Group at 888-320-5938 and we will help you with the purchase.